Ultraseal – The Most Hygienic Seaming Rolls On The Market

The most advanced seaming roll in the industry. Fit and forget technology for next generation performance and profitability. Combined with either Eco or Evo seal, this unique seal package creates two lines of defence on oil or grease lubricated seamers reducing the risk of product/ water ingress in the bearing and lubrication contamination in the seamer. A cleaner seamer and longer operational seaming roll life!

|

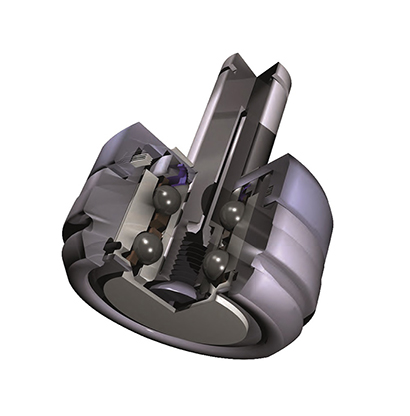

Ceramic bearing

Titanium Coatings (CVD applied)

Eco seal

Evo seal

Ultraseal

|

GREASE – Eco seal and Ultraseal example

Below is evidence of a customer who trialled one station of Ultraseal tooling on their Angelus seamer. The tooling created less grease fly which reduced the risk of contamination and reduced the frequency of re-greasing.

Significant Savings on Grease Plus a Cleaner Seamer!

A working example (in beer/beverage) adhering to CMB tooling care issue document:

| With Eco seal Greasing frequencies = 1 to 2 grams every 144 hours of operation. A filling company runs 1200 cans per minute on an Angelus 121L (12 heads) at a production efficiency of 80%. Including efficiency losses and product/diameter changes, this machine closes 1200 cpm constantly for 16 hours a day, 5 days a week.

Annual lubrication quantity = 29 x 2 grams = 58 grams per year for 299,520,000 cans seamed. |

With Eco seal and Ultraseal Greasing frequencies = 4 to 8 grams every 6 months of operation. A filling company runs 1200 cans per minute on an Angelus 121L (12 heads) at a production efficiency of 80%. Including efficiency losses and product/ diameter changes, this machine closes 1200 cpm constantly for 16 hours a day, 5 days a week.

Annual lubrication quantity = 2 x 8 grams = 16 |

Get in touch with the Seamer Tooling department today:

Email us: seaming@cmbe.com

Call us: UK: +44(0)1274 846200 | US: +1(203) 853-7325 | China: + (86) 13818526370