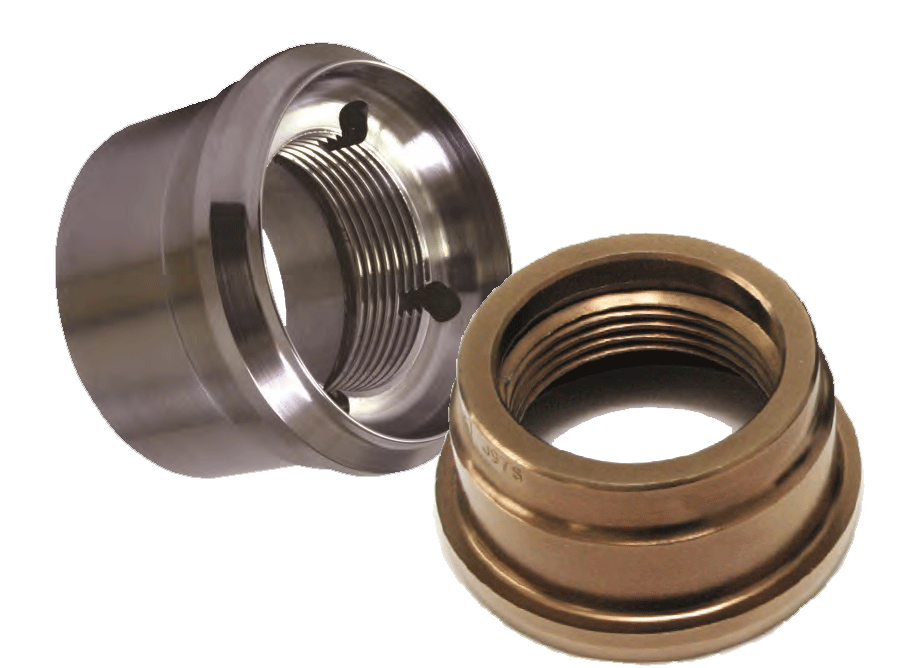

Precision Seaming Chucks

Each Chuck Is Manufactured For A Specific End Design

Chucks have been designed and made against specific customer requirements for almost any can/ end combination and for most common seamers including Ferrum, Angelus, FMC and Metalbox.

Each chuck is manufactured for a specific end design and can be specially customised for end type or supplied against a recognised industry standard manufacturing drawing.

- STELLITE (STOODY) NON-INTERLOCKING

- AVAILABLE NON-COATED OR COATED (CVD PROCESS)

- TITANIUM NITRIDE (SAT) COATING

- TITANIUM CARBIDE (ARC) COATING

- TEXTURED TTA/TTC OR NON TEXTURED CHUCK LIP

Advanced Seaming Rolls

Making Seamer Tooling For The Harshest Conditions

CMB Seaming Rolls have been developed to perform in the harshest conditions. Rolls can be supplied for all common seamers in use across the industry.

The grade of Stellite (Stoody) material has been specially developed to ensure the best possible grain structure and properties for the rollprofile. Titanium Carbide provides the most cost effective coating and is highly resistant to wear, cracking or flaking. Ceramic bearings combined with the unique ‘Eco seal’ / ‘Evo seal’ and Ultraseal are essential in achieving the very best seaming roll operational performance. CMB has extensive experience across all products and materials including aluminium, steel, plastic & composite can combinations. We work with our customers to provide roll profiles best suited to achieve their specific double seam.

• STELLITE (STOODY)

• DESIGNED TO SUIT EACH SEAMER TYPE

Get in touch with the Seamer Tooling department today:

Email us: seaming@cmbe.com

Call us: UK: +44(0)1274 846200 | US: +1(203) 853-7325 | China: + (86) 13818526370